Multi-Storeys Constructed with Thermocol could be the future Earthquake-resistant Buildings

Multi-Storeys Constructed with Thermocol could be the future Earthquake-resistant Buildings

Posted On: 23 AUG 2021 , Delhi

Thermocol could be the material of the future for construction of earthquake-resistant buildings, with thermal insulation and could also save energy required to develop construction materials.

Researchers at IIT Roorkee have found that thermocol or Expanded Polystyrene (EPS) is used as a composite material in core of reinforced concrete sandwich, could resist earthquake forces on up to four-storey buildings.

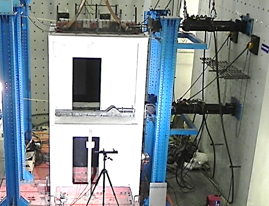

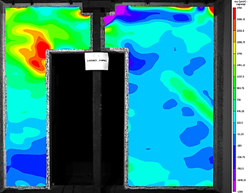

The researchers tested a full-scale building and a number of wall elements constructed with thermocol sandwiched between two layers of concrete at the National Seismic Test Facility (NSTF) of the Department of Earthquake Engineering, IIT Roorkee, developed under Fund for Improvement of S&T Infrastructure (FIST) programme of Department of Science & Technology (DST), Government of India. Mr Adil Ahmad, the research Scholar who conducted the tests, evaluated the behaviour of the constructions under lateral forces, as earthquake causes a force predominantly in lateral direction. The investigation was supplemented with detailed computer simulation of a realistic 4-storey building. Prof. Yogendra Singh, supervising the research, informed that the analysis shows that a four-storey building constructed with this technique is capable of resisting earthquake forces, even in the most seismic zone (V) of the country, without any additional structural support.

They have attributed this earthquake resistance capability to the fact that the EPS layer is sandwiched between two layers of concrete having reinforcement in the form of welded wire mesh. The researchers said that the force being applied on a building during an earthquake arises due to the inertia effect and hence depends on the mass of the building. Thermocol resists earthquakes by reducing the mass of the building.

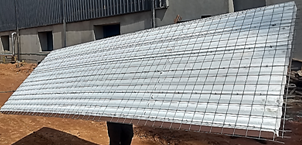

In this technique, the EPS core and the wire mesh reinforcement is produced in a factory. The building skeleton is first erected from the factory-made core and reinforcement panels, and then concrete is sprayed on the skeleton core. This technique does not require any shuttering and hence can be constructed very fast.

Besides resisting earthquakes, the use of expanded polystyrene core in concrete walls of a building can result in thermal comfort. The core provides the necessary insulation against the heat transfer between building interior and exterior environment. This can help in keeping the building interiors cool in hot environments and warm during cold conditions. India suffers a large variation of temperature in different parts of the country and during different seasons of the year. Therefore, thermal comfort is a crucial consideration along with structural safety.

The technology also has the potential of saving construction material and energy, with an overall reduction in carbon footprint of buildings. It replaces a large portion of concrete volume from the walls and floor/roof. This replacement of concrete with the extremely lightweight EPS not only reduces mass, thereby decreasing the earthquake force acting on a building but also diminishes the burden on the natural resources and energy required to produce the cement concrete.

|  |

| |

| Fig. 1 Factory made EPS core panel and welded wire mesh reinforcement | Fig. 2 Building skeleton made of factory-made EPS core panels |

|  |

Fig. 3 Spraying and pouring of concrete over the EPS core skeleton and finished building model

|  |

Fig. 4 Testing of the full-scale building model in the NSTF and strain pattern obtained using the contactless Digital Image Correlation system procured through DST-FIST support